suave faulksy

bet you can't wait to be rolling.

epilogue to your fuel pump re-co job.

i've pulled three apart so far.

a 009 for 74 914 1.8.

a 005 from a saab 99 ems (but also fitted to early 914s).

and a more ancient merc one with a slightly different port set up but more or less same as others.

they are all different inside in an evolutionary way. the 009 has the most compact electric armature and magnets.

i believe the 009 might be the last evolution of the type. i know a 010 is the inline type of the modern layout with 2 ports, one at each end.

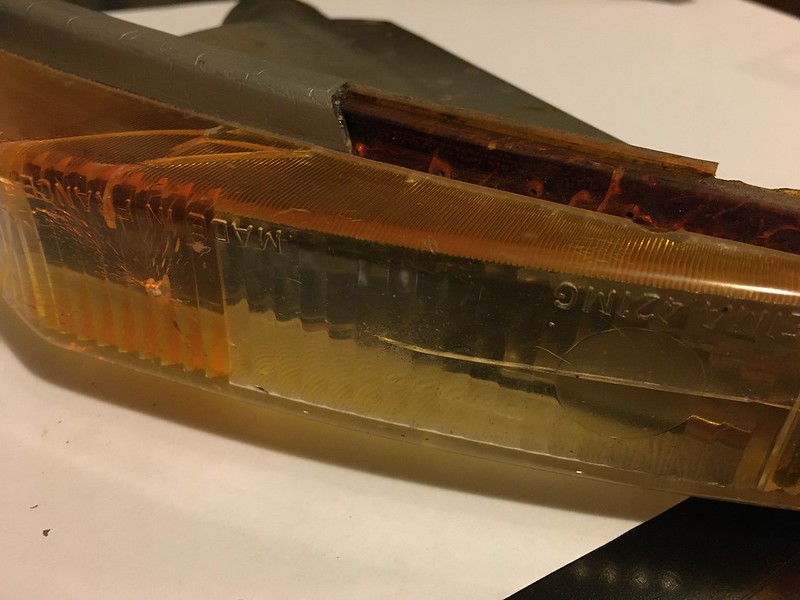

these pics are inside the 005.

i have a tip for anyone who wants to have a go like faulksy and pull one of these apart to fix it.

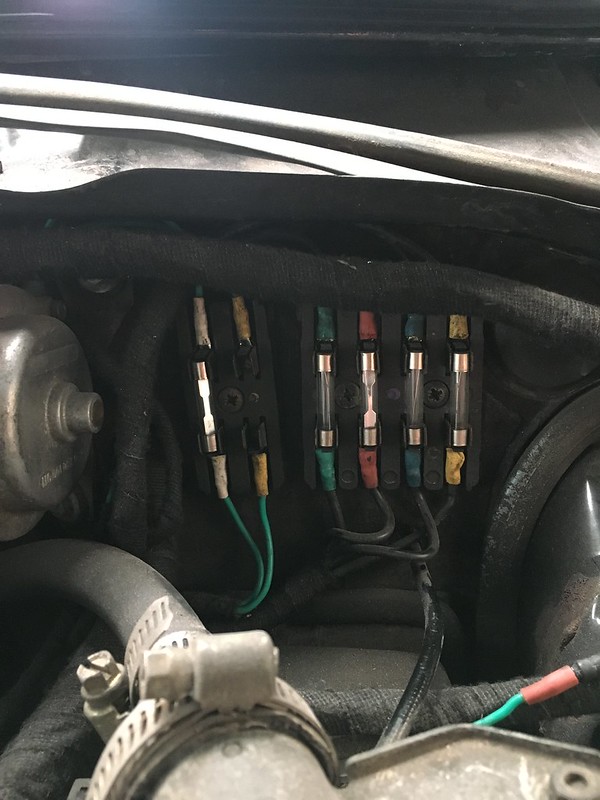

when you get down to the last bit, which is the electrical plug, what you should do is snip the wire to the electrical plug in the base of the unit. to do that you have to disassemble it more than faulksy did by driving out the little pin that holds the shaft of the motor assembly to the base of the port section. once you do that you can easily get inside the section that contains the electrical plug.

in all three pumps i have disassembled the electrical plug is wired into a rivet or stamped plug. you snip that wire and then you don't run the risk of tearing it out of the plug when you pull the plug out to do the last o-ring.

you can resolder it on reassembly.

(which i have yet to do).

bet you can't wait to be rolling.

epilogue to your fuel pump re-co job.

i've pulled three apart so far.

a 009 for 74 914 1.8.

a 005 from a saab 99 ems (but also fitted to early 914s).

and a more ancient merc one with a slightly different port set up but more or less same as others.

they are all different inside in an evolutionary way. the 009 has the most compact electric armature and magnets.

i believe the 009 might be the last evolution of the type. i know a 010 is the inline type of the modern layout with 2 ports, one at each end.

these pics are inside the 005.

i have a tip for anyone who wants to have a go like faulksy and pull one of these apart to fix it.

when you get down to the last bit, which is the electrical plug, what you should do is snip the wire to the electrical plug in the base of the unit. to do that you have to disassemble it more than faulksy did by driving out the little pin that holds the shaft of the motor assembly to the base of the port section. once you do that you can easily get inside the section that contains the electrical plug.

in all three pumps i have disassembled the electrical plug is wired into a rivet or stamped plug. you snip that wire and then you don't run the risk of tearing it out of the plug when you pull the plug out to do the last o-ring.

you can resolder it on reassembly.

(which i have yet to do).