I'll be working on this over the next few months after hours. It might not interest many but I know a few will like it, so here goes:

The Plan:

I own a series 1 205 Gti with the DFZ 1.9l in it. I’ve had it for nearly four months now and as most of you would know who own one, they really are great cars. I love it and choose to drive it over and above my other ride, an evo 7, more often than not.

The thing drives great, is clean and I reckon it probably has one of the best original interiors going around: all the electrics work (now), no tears or cracks or anything. I even have the original books and the tape deck which will go back in soon.

The throttle response is excellent and is the first thing I noticed when I drove it for the first time. The DFZ leaves you wanting in power though and that was what prompted this project.

I want to keep it street so I don’t want a dyno queen or a stripped out track mongrel: just a good torquey car that I can surprise a few people off the line with, and go out to an occasional track day without getting too far left behind.

The first and most glaring problem to address is the shockingly low compression. 8.4:1 would be well suited to a forced induction set-up but I really don’t want to go down that road – I love the sound and throttle response of a nicely tuned naturally aspirated engine so decided to travel that road.

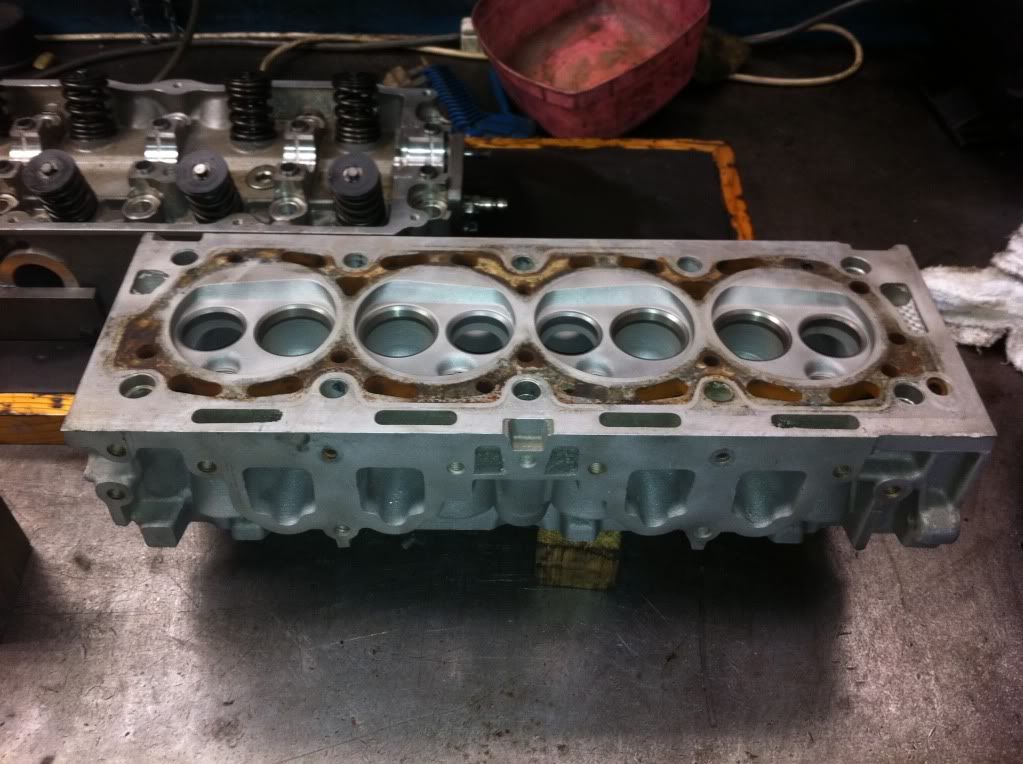

Thanks to the very helpful info provided by some Aussie Froggers, I found out the series 3 GTi’s (and the 1.6’s) had the DKZ high compression engine: the cylinder head had smaller chambers raising the compression ratio to 9.2:1. If you bolt one of these onto the DFZ bottom end it jumps the CR to somewhere around 10.5:1 due to the smaller dishes in the pistons of the DFZ.

I have the rare opportunity to use a fully equipped machine shop after hours (I’m a final year apprentice of Automotive Machining in my family business) so for me the most economical way to extract power is through a nicely thought-out cylinder head build. The only cost would be in the parts used.

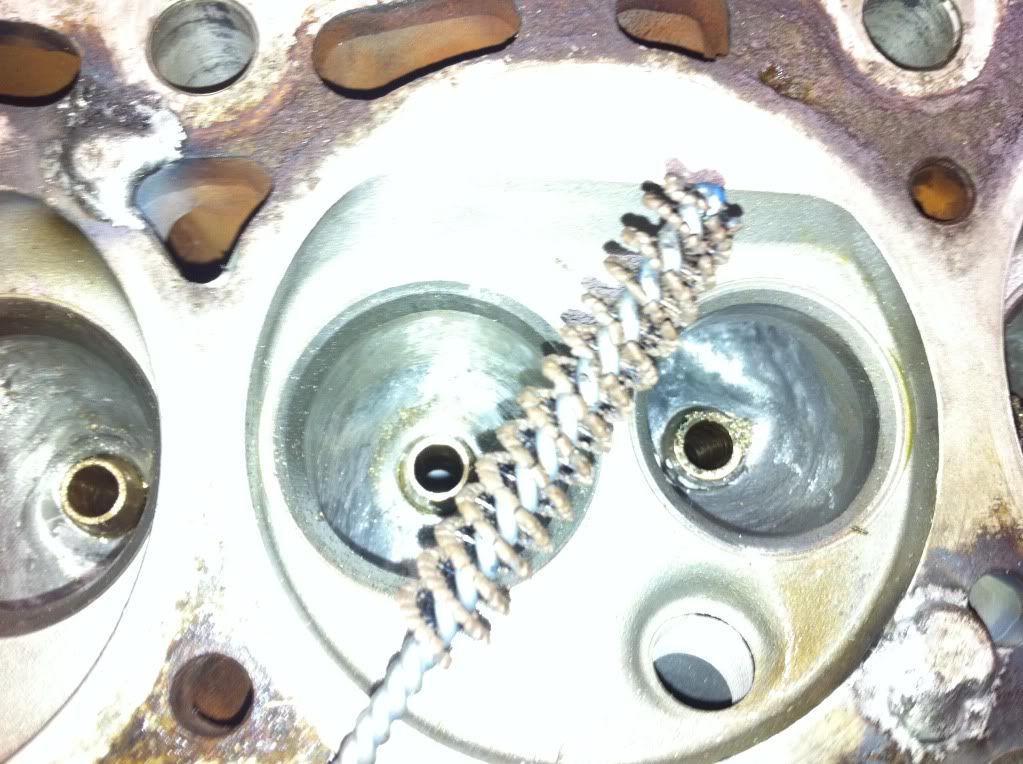

After some thought I decided I’d perhaps try and contribute some quantitative evidence for or against ‘big-valve heads’ (BVH) for the XU9 8v. My dad made a pretty nice flow bench that we use in the shop every now and then usually for in-house development on certain cylinder heads. Although it is pretty well-calibrated, I reckon the only real way to come up with absolute figures that are genuinely comparable would be for me to compare a stock valve head to a BVH on the same bench. Stage 2 of this project, which will be a complete rebuild, will also include some pretty extensive testing on our engine dyno, once again comparing actual power outputs of any modifications.

I subscribe to the idea that it is most helpful to view an engine as an air pump. The more air the engine can pump per RPM the more ‘efficient’ it is in making power. So obviously big inlet valves are going to help if you subscribe to this theory. I’m also aware though, that this can be overly simplistic and there are a variety of variables such as entry angles, swirl, turbulence and very importantly velocity that all come into play. The classic old-school example is that a Holden 253 without any other modifications runs better and makes more power with the stock heads than with the 308 big valve/port heads, all because of air speed.

The Plan:

I own a series 1 205 Gti with the DFZ 1.9l in it. I’ve had it for nearly four months now and as most of you would know who own one, they really are great cars. I love it and choose to drive it over and above my other ride, an evo 7, more often than not.

The thing drives great, is clean and I reckon it probably has one of the best original interiors going around: all the electrics work (now), no tears or cracks or anything. I even have the original books and the tape deck which will go back in soon.

The throttle response is excellent and is the first thing I noticed when I drove it for the first time. The DFZ leaves you wanting in power though and that was what prompted this project.

I want to keep it street so I don’t want a dyno queen or a stripped out track mongrel: just a good torquey car that I can surprise a few people off the line with, and go out to an occasional track day without getting too far left behind.

The first and most glaring problem to address is the shockingly low compression. 8.4:1 would be well suited to a forced induction set-up but I really don’t want to go down that road – I love the sound and throttle response of a nicely tuned naturally aspirated engine so decided to travel that road.

Thanks to the very helpful info provided by some Aussie Froggers, I found out the series 3 GTi’s (and the 1.6’s) had the DKZ high compression engine: the cylinder head had smaller chambers raising the compression ratio to 9.2:1. If you bolt one of these onto the DFZ bottom end it jumps the CR to somewhere around 10.5:1 due to the smaller dishes in the pistons of the DFZ.

I have the rare opportunity to use a fully equipped machine shop after hours (I’m a final year apprentice of Automotive Machining in my family business) so for me the most economical way to extract power is through a nicely thought-out cylinder head build. The only cost would be in the parts used.

After some thought I decided I’d perhaps try and contribute some quantitative evidence for or against ‘big-valve heads’ (BVH) for the XU9 8v. My dad made a pretty nice flow bench that we use in the shop every now and then usually for in-house development on certain cylinder heads. Although it is pretty well-calibrated, I reckon the only real way to come up with absolute figures that are genuinely comparable would be for me to compare a stock valve head to a BVH on the same bench. Stage 2 of this project, which will be a complete rebuild, will also include some pretty extensive testing on our engine dyno, once again comparing actual power outputs of any modifications.

I subscribe to the idea that it is most helpful to view an engine as an air pump. The more air the engine can pump per RPM the more ‘efficient’ it is in making power. So obviously big inlet valves are going to help if you subscribe to this theory. I’m also aware though, that this can be overly simplistic and there are a variety of variables such as entry angles, swirl, turbulence and very importantly velocity that all come into play. The classic old-school example is that a Holden 253 without any other modifications runs better and makes more power with the stock heads than with the 308 big valve/port heads, all because of air speed.