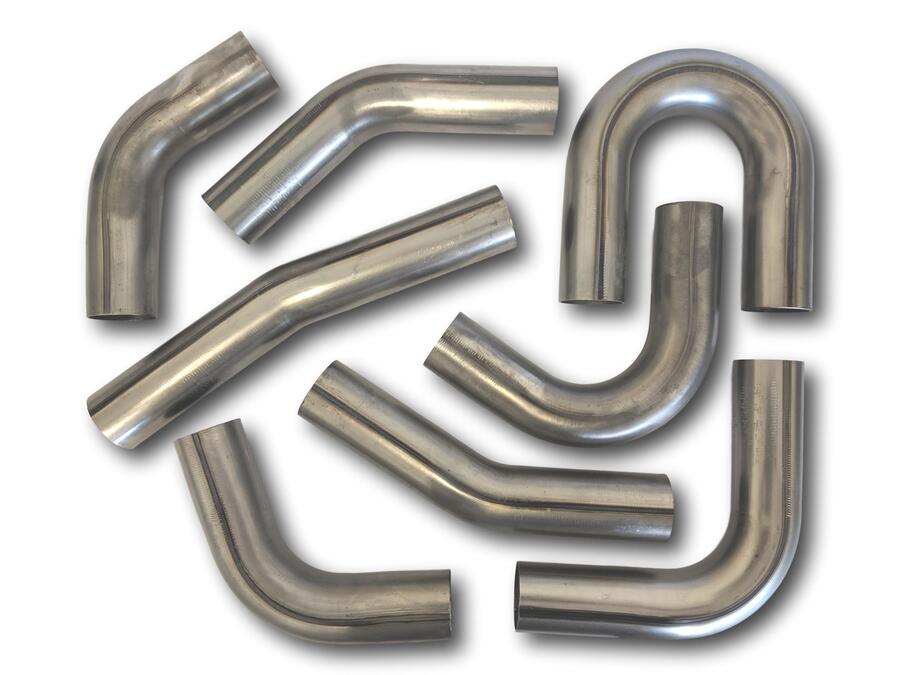

I don't suppose anyone in Sydney has a tube bender that can bend 32mm OD aluminium tube with 1.6mm walls?

Or even know what sort of bender will do the job? The standard hydraulic ones can be picked up pretty cheap but I suspect the manual type used for roll cages etc would be better. Maybe even a 1 1/4" steel conduit bender will work.

Or even know what sort of bender will do the job? The standard hydraulic ones can be picked up pretty cheap but I suspect the manual type used for roll cages etc would be better. Maybe even a 1 1/4" steel conduit bender will work.