If you have an ultrasonic bath I would suggest you have nothing to lose by chucking the pump in your favourite cleaner (I would try WD40 to start with) and see if the gunk comes out. I suspect gunk from stale petrol has solidified in the pump but it should be otherwise okay.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BX Time - '89 16v project

- Thread starter faulksy

- Start date

what do people think is the best ultra sonic cleaner fluid .

I though meth or carbon tetra chloride (maybe a bit toxic) does it need to be a solvent ?

I though meth or carbon tetra chloride (maybe a bit toxic) does it need to be a solvent ?

I’ve made a rookie error and managed to trap (and squash) the pipe between the HP pump and the FDV when refitting the gearbox. Thought I’d tied them up high enough but apparently not. It did seem strange that the last gearbox bolt was harder to get in than the rest.

The upshot of that is I now need to make a new pipe or beg someone for one off a wreck. Does anyone know what OD of the pipe is?

The upshot of that is I now need to make a new pipe or beg someone for one off a wreck. Does anyone know what OD of the pipe is?

FWIW (and at the risk of reviving an old thread - there's an error on the circuit board that means the full speed override relay never turns on. I have a fix which (from memory) involves cutting a track on the board. The circuit diagram in the manual is correct - it's the manufacturing of the board that's wrong. If you're interested, I'll dig out the fix. It's somewhere in the archive...Next on the electrical hit list, the cabin fans have spotaneously stopped working.

First port of call is out friend the junction box to check F2.

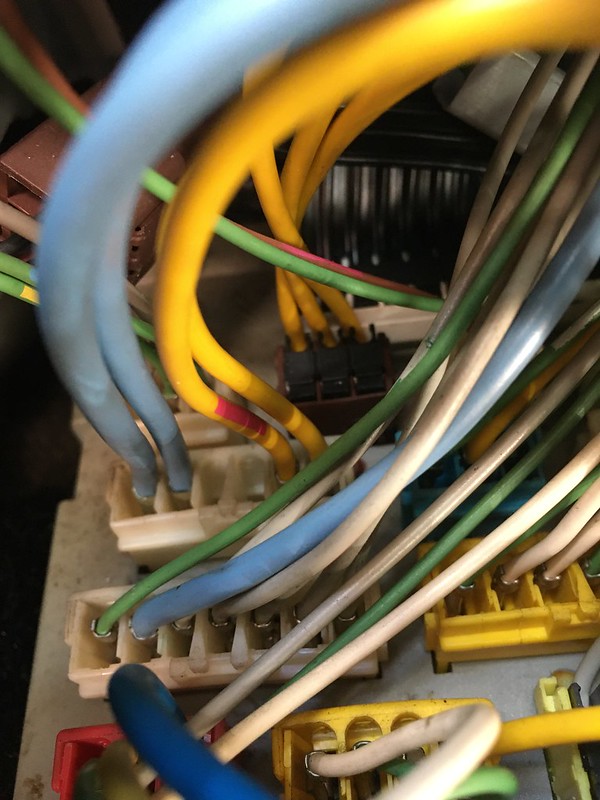

Not an ideal situation but it does at least work. I nabbed F7and swapped it in just to check, no change. So out with the mulitmeter to go voltage hunting. There was 12v on one site of the fuse so that's a good start. Power from F2 goes out to the fans via the two yellow cables of this connector in column 3

There was power there so on to the next item in the chain which is the fans themselves. The control gear is all on the earth side of the circuit. Both had 12v at the connectors. Having just reassembled the dashboard, it now has to come apart again to get at the fan controls.

Pins 1 and 3 are earths which were both fine. Apparently a missing earth on pin 3 is fairly common. Pin 2 is power for the lighting. Pins 4 and 5 control the fans.

Everything checked fine here and yet the fans still refused to spin. The full speed relay on the back of the steering column seemed ok but wasn't doing a whole lot. Seems they are a bit redundant anyway.

Drastic measures are required, I disconnected on of the fans and rigged up a connection direct to the battery, still no life so it appears the fans are the problem. The next step is to yank them out of the scuttle and see what's what

what do people think is the best ultra sonic cleaner fluid .

I though meth or carbon tetra chloride (maybe a bit toxic) does it need to be a solvent ?

Don't even think about tetrachloride. That stuff is nasty. Like, properly nasty. For you I mean, forget environment and all that.

Anything that dissolves stuff is good, even straight diesel. You want to just give the bath a chance to shake away the dirt. Dishwashing soap is fine.

I had heard that Duncan. It depends who made the board, some are fine and others have the fault you mentioned. This one seems to work fine even if the A/C itself doesn’t.

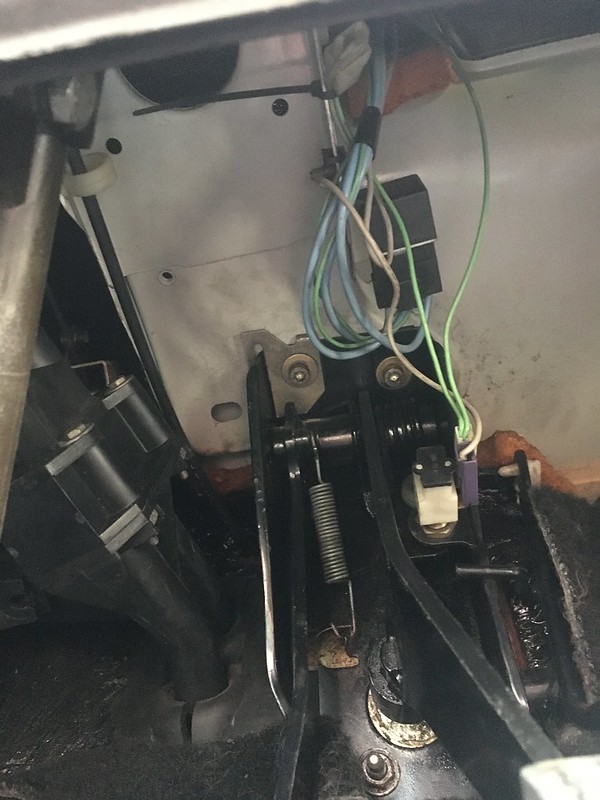

For those playing at home you may remember I mentioned the clutch being a problem. Well, after taking the box out twice, crushing the pump output pipe in the process and spraining my thumb it turns out the only problem was the monkeys at the last Citroen workshop to service the car didn’t fit the clutch cable properly. Clipped the cable sheath back into the gearbox and it’s now rather nice to drive.

For those playing at home you may remember I mentioned the clutch being a problem. Well, after taking the box out twice, crushing the pump output pipe in the process and spraining my thumb it turns out the only problem was the monkeys at the last Citroen workshop to service the car didn’t fit the clutch cable properly. Clipped the cable sheath back into the gearbox and it’s now rather nice to drive.

Does anybody know what holds the fule pump and filter in place? Both are inserted into a rubber block which is just resting on a hook on the subframe. I would have thought there would be a clamp or something to stop the assembly falling out of the subframe.

Thanks Dave. the heat shield fell off whilst giving the pump a technical tap. Didn’t realise it was integral to holding the pump onto the car! I’m surprised that it’s basically just a rubber band holding the pump in place. Now, which box did I put it in….

While under the car I noticed a section of rather crusty wiring that was only half heartedly connected to the oil temp and level sensors. Neither gauge was working so figured this might be the cause. Pulling the wiring back through the engine bay and out of the sheathing revealed this mess

Who tries to glue wires back together with silicone!!?? They weren’t even twisted together and then smeared with goop!

After splicing some new wires in the level gauge and temp gauge have come to life but it doesn’t look like the oil pressure gauge is swapping to “pressure” mode. The needle stays pegged at max. How is the gauge supposed to work?

Who tries to glue wires back together with silicone!!?? They weren’t even twisted together and then smeared with goop!

After splicing some new wires in the level gauge and temp gauge have come to life but it doesn’t look like the oil pressure gauge is swapping to “pressure” mode. The needle stays pegged at max. How is the gauge supposed to work?

I just consulted my handy BX handbook.

The gauge is supposed to read oil level for 2 seconds after you switch the ignition on, then reverts to read oil pressure. In practice I have found it all a bit dodgy, especially as the oil pressure senders are now about 35 years old and the internal connections are a bit dirty/worn.

Cheers, Ken

The gauge is supposed to read oil level for 2 seconds after you switch the ignition on, then reverts to read oil pressure. In practice I have found it all a bit dodgy, especially as the oil pressure senders are now about 35 years old and the internal connections are a bit dirty/worn.

Cheers, Ken

i had that problem with the wiring with my MI 16 its a very hot environment down the back there ,

Are you sure that's not just melted plastic insulation? As pugwash says, could have been caused by engine heat, but also looks like the results of a short...While under the car I noticed a section of rather crusty wiring that was only half heartedly connected to the oil temp and level sensors. Neither gauge was working so figured this might be the cause. Pulling the wiring back through the engine bay and out of the sheathing revealed this mess

View attachment 220583

View attachment 220584

Who tries to glue wires back together with silicone!!?? They weren’t even twisted together and then smeared with goop!

After splicing some new wires in the level gauge and temp gauge have come to life but it doesn’t look like the oil pressure gauge is swapping to “pressure” mode. The needle stays pegged at max. How is the gauge supposed to work?

RUNS REAL CLOSE TO THOSE 8 EXHAUST PIPES COMEING OUT OF THE HEAD AND DOWN CLOSE TO THE ENGINE BLOCK

Ok - enlarged the photo, and can now see that the original insulation was (very thin) grey plastic, which hasn't melted, but is brittle (cracks and missing segments visible). As you said, the white stuff must be silicon - most likely bathroom sealant, not designed to withstand heat.Are you sure that's not just melted plastic insulation? As pugwash says, could have been caused by engine heat, but also looks like the results of a short...

The original insulation was a bit baked and cracked but definitely not melted. The loom had a protective sheath around it which turned to dust as soon as I looked at it. The original wires are actually brown and green, just very dirty.

I’ll have to see what the oil gauge does if I unplug the pressure sender. Prior to fixing the wiring it did absolutely nothing. It’s now showing some life which is promising

I’ll have to see what the oil gauge does if I unplug the pressure sender. Prior to fixing the wiring it did absolutely nothing. It’s now showing some life which is promising

There's a daughter board on the back of the oil pressure gauge with an SGS Thomson IC on it that has a non-standard part number. I assume it's a quad op amp package. That's the board that reads the oil level and does the timed gubbins that switches to oil pressure. And it blows up if cack-handed people try and 'test' the oil pressure gauge.The original insulation was a bit baked and cracked but definitely not melted. The loom had a protective sheath around it which turned to dust as soon as I looked at it. The original wires are actually brown and green, just very dirty.

I’ll have to see what the oil gauge does if I unplug the pressure sender. Prior to fixing the wiring it did absolutely nothing. It’s now showing some life which is promising

FWIW, I have two instrument clusters with exactly the same problem: the fascia bulges out ever so slightly and fouls the indicator needle enough to restrict its movement. I've had one cluster repaired a couple of times (a mob out in Ringwood) but the glue the repairers use fails and it's back to bulging and jamming the needle.