Hi everyone,

Stashed away in my shed for the past few years has been a 1987 505 GTi automatic sedan, in grey. It has zero rust, is straight as a die, and has an immaculate grey interior. The clear coat is a bit tired, but other than that it is a nice, clean car.

I've decided it's time to put it on the road, but to give it a bit of a lift first. So, I have decided to install a V6 and convert to manual. I'm not building a racecar here, I just think that a stock V6 running stock engine management through a 5 speed gearbox would just be a lovely thing.

So as to avoid too much clutter in the shed, I'm building up the replacement drivetrain before even moving the car down to the main shed. Hopefully this will mean I will be able to just swap drivetrains in a very short time.

The engine I am fitting is a 3.0 litre PRV V6 from a 605. I will run the standard 605 engine management system, and apart from swapping the lower sections over with those from a 604 engine, moving the distributor from the back of the head to the front, and some modifications to the inlet tract to physically fit it into the 505 engine bay, the whole engine will be standard. The only change I want to make is to swap over the positions of the alternator and the power steering pump, so that the pump is on the same side as the power steering rack, and the alternator is on the same side as the battery and starter. I would also like to preserve the serpentine belt setup from the 605 as much as possible.

The gearbox is a RHD BA10/5 from a 604. The flywheel I imported from Spain, and is from a 605 SV24 manual. I will have to drill the bellhousing to accept the crank angle sensor. I have bought a new Quaife LSD to help the back end behave.

I have set up this thread as somewhere to dump photos of the process, so watch this space!

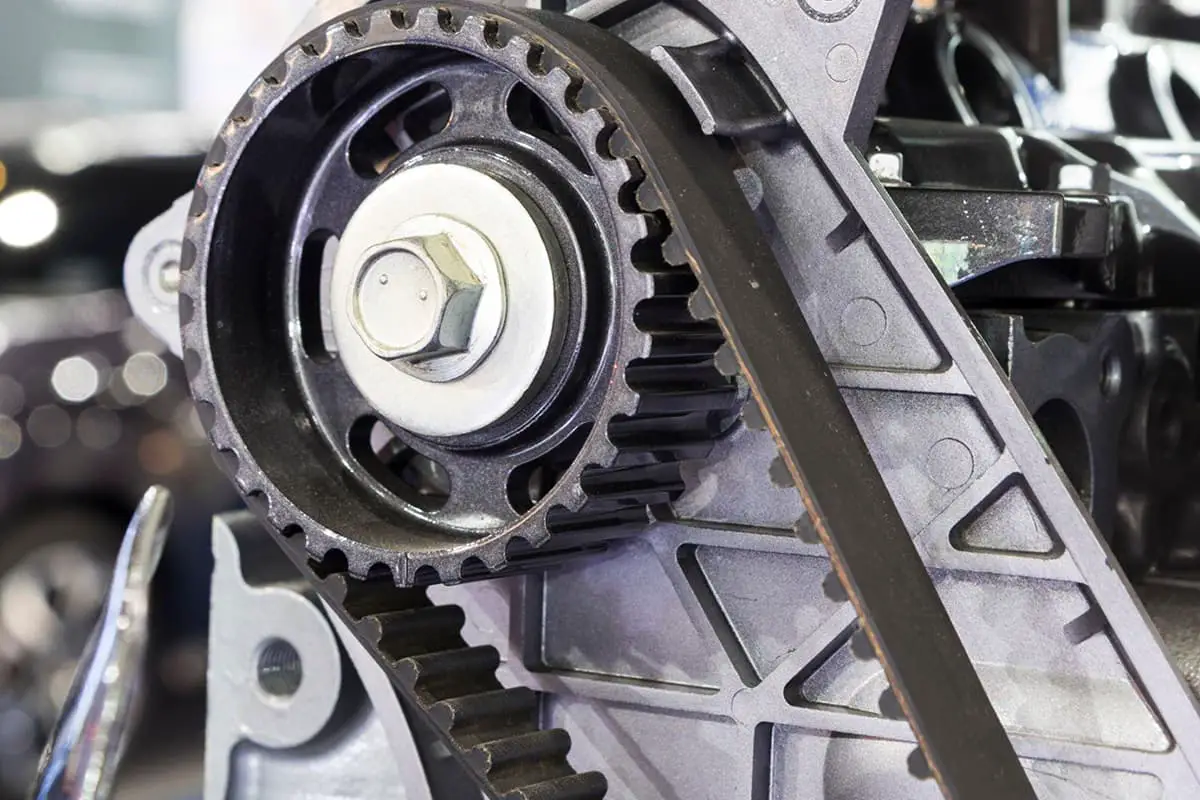

The first photo: The very filthy 605 engine awaiting preparation:

Stashed away in my shed for the past few years has been a 1987 505 GTi automatic sedan, in grey. It has zero rust, is straight as a die, and has an immaculate grey interior. The clear coat is a bit tired, but other than that it is a nice, clean car.

I've decided it's time to put it on the road, but to give it a bit of a lift first. So, I have decided to install a V6 and convert to manual. I'm not building a racecar here, I just think that a stock V6 running stock engine management through a 5 speed gearbox would just be a lovely thing.

So as to avoid too much clutter in the shed, I'm building up the replacement drivetrain before even moving the car down to the main shed. Hopefully this will mean I will be able to just swap drivetrains in a very short time.

The engine I am fitting is a 3.0 litre PRV V6 from a 605. I will run the standard 605 engine management system, and apart from swapping the lower sections over with those from a 604 engine, moving the distributor from the back of the head to the front, and some modifications to the inlet tract to physically fit it into the 505 engine bay, the whole engine will be standard. The only change I want to make is to swap over the positions of the alternator and the power steering pump, so that the pump is on the same side as the power steering rack, and the alternator is on the same side as the battery and starter. I would also like to preserve the serpentine belt setup from the 605 as much as possible.

The gearbox is a RHD BA10/5 from a 604. The flywheel I imported from Spain, and is from a 605 SV24 manual. I will have to drill the bellhousing to accept the crank angle sensor. I have bought a new Quaife LSD to help the back end behave.

I have set up this thread as somewhere to dump photos of the process, so watch this space!

The first photo: The very filthy 605 engine awaiting preparation: